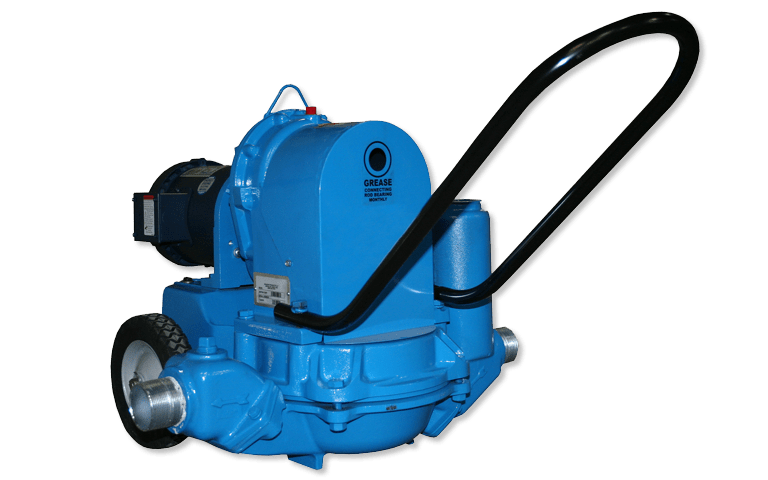

When a Mud Hog Diaphragm Pump Starts Losing Its Bite, One Part Usually Takes the Blame.

On a muddy jobsite, nobody has time for a pump that “kind of” works. The water isn’t clean, the pit isn’t shallow, and the crew isn’t waiting around because a machine decided to get picky. That’s why diaphragm pumps, especially Mud Hog-style models, keep showing up in the same places: construction sites, industrial cleanup, slurry work, and anywhere water is mixed with whatever the day throws into it. But even these pumps have a predictable breaking point. It isn’t mysterious, and it isn’t rare. The diaphragm, the flexible part inside the pump that creates the pumping action, wears out. Not because the pump is poorly built, but because that diaphragm is constantly moving, constantly flexing, and constantly getting punished by grit, silt, sand, and heavy cycling. In tough conditions, replacing a diaphragm isn’t a surprise repair. It’s normal maintenance. Most customers don’t go shopping for a replacement diaphragm casually. They go