This instruction sheet provides you with the information required to safely own and operate your Red Lion pump. Retain these instructions for future reference. The Red Lion pump you have purchased is of the highest quality workmanship and material, and has been engineered to give you long and reliable service. Red Lion pumps are carefully tested, inspected, and packaged to ensure safe delivery and operation. Please examine your pump carefully to ensure that no damage occurred during shipment. If damage has occurred, please contact the place of purchase. They will assist you in replacement or repair, if required.

READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL , OPERATE , OR SERVICE YOUR Red Lion PUMP. KNOW THE PUMP’S APPLICATION, LIMITATIONS, AND POTENTIAL HAZARDS. PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH THESE INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE!

Please refer to your Red lion Sump Pump owner’s manual for installation and operation of your sump pump. These instructions cover set-up of the dual pumping system only.

Step 1: Unpack the plumbing kit and each sump pump. Store the extra float stop in a safe place (see Fig. 1).

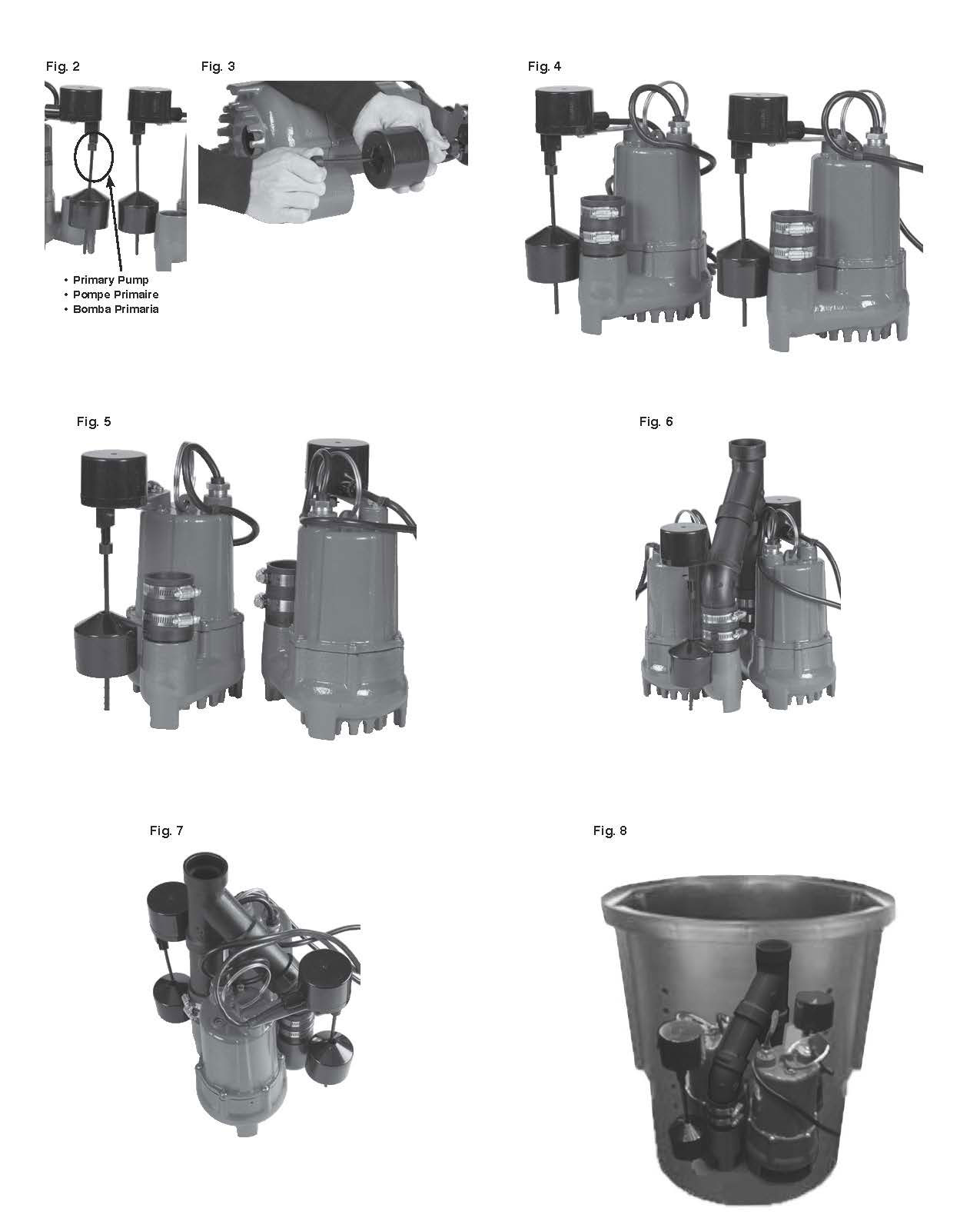

Step 2: Using PTFE tape, secure the black check valves into each sump pump by threading them into the discharge of each pump (Fig. 4).

Step 3: Align the pumps so the two discharge units line up with the piping as shown in (Fig. 5). Install the ABS piping into each check valve (Fig. 6).

DO NOT TIGHTEN THE CLAMPS YET.

Step 4: Twist the pump to eliminate the spacing between them (Fig. 7). Once pumps are tight against the piping, tighten the clamps at both the top and the bottom of each piping unit using a flat head screwdriver.

Step 5: Install into the sump pit. Diameter of the sump pit must be a minimum of 18” (Fig. 8). Plug both units into GFCI electrical outlet. Test the GFCI outlet to pressing the Test button. Be sure to reset the GFCI by pressing the Reset switch.

SAFETY GUIDELINES

RISK OF ELECTRIC SHOCK:

Do not use an extension cord.

When a pump is in a basin or lift station, do not touch motor, pipes, or water until unit is unplugged or shut off. If shut-off box is not accessible, call the electric company to shut off service to the house or call your local fire department for instructions. Failure to follow this warning can result in fatal electrical shock.

Do not modify the power cord except to shorten it to fit into a control panel. Any splice between the pump and the control panel must be made within a junction box and mounted outside of the basin, and comply with the National Electrical Code. Do not use the power cord for lifting the pump.

The pump motor is equipped with an automatic resetting thermal protector and may restart unexpectedly. Protector tripping is an indication of motor

overloading as a result of excessively high or low voltage, inadequate wiring, incorrect motor connections, or a defective motor or pump.

1. Read all instructions and safety guidelines thoroughly. Failure to follow the guidelines and instructions could result in serious bodily injury and/or property damage.

2. DO NOT USE TO PUMP FLAMMABLE OR EXPLOSIVE FLUIDS SUCH AS GASOLINE, FUEL OIL, KEROSENE, ETC. DO NOT USE IN EXPLOSIVE ATMOSPHERES OR HAZARDOUS LOCATIONS AS CLASSIFIED BY NEC, ANSI/NFPA70. FAILURE TO FOLLOW THIS WARNING CAN RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE.

3. During normal operation the opump is immersed in water. Also during rain storms, water may be present in the surrounding area of the pump.

Use caution to prevent bodily injury when working near the pump:

a. Remove the plug from the receptacle prior to touching, servicing, or repairing the pump.

b. To minimize possible fatal electrical shock hazard, use extreme care when changing fuses. Do not stand in water while changing fuses or

insert your finger into the fuse socket.

4. Do not operate the pump in a dry basin. This will cause the pump to become extremely hot, causing burns if touched and/or damage to the pump.