APPLICATIONS

Ideal for the supply of fresh water to rural homes, farms, and cabins that have suction lifts down to 90′.

FEATURES & BENEFITS

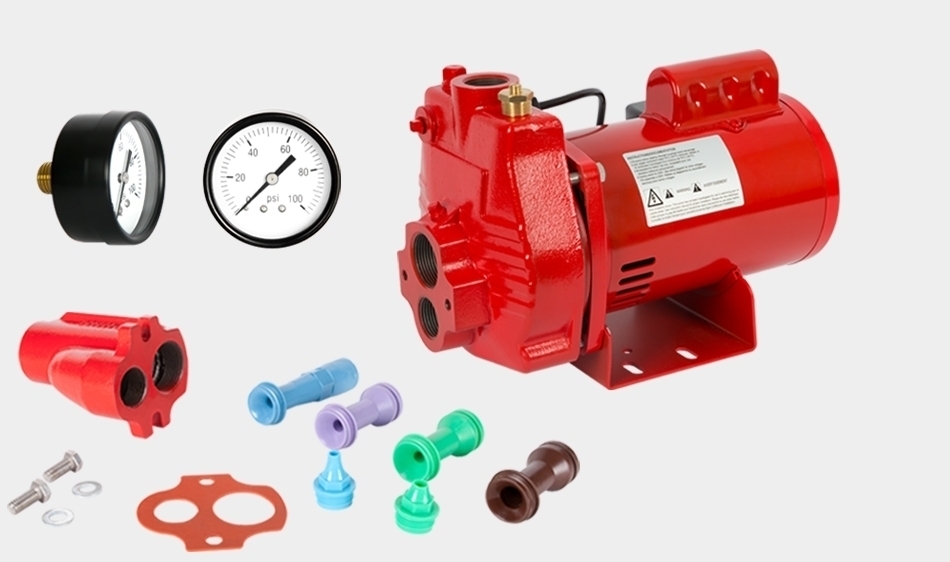

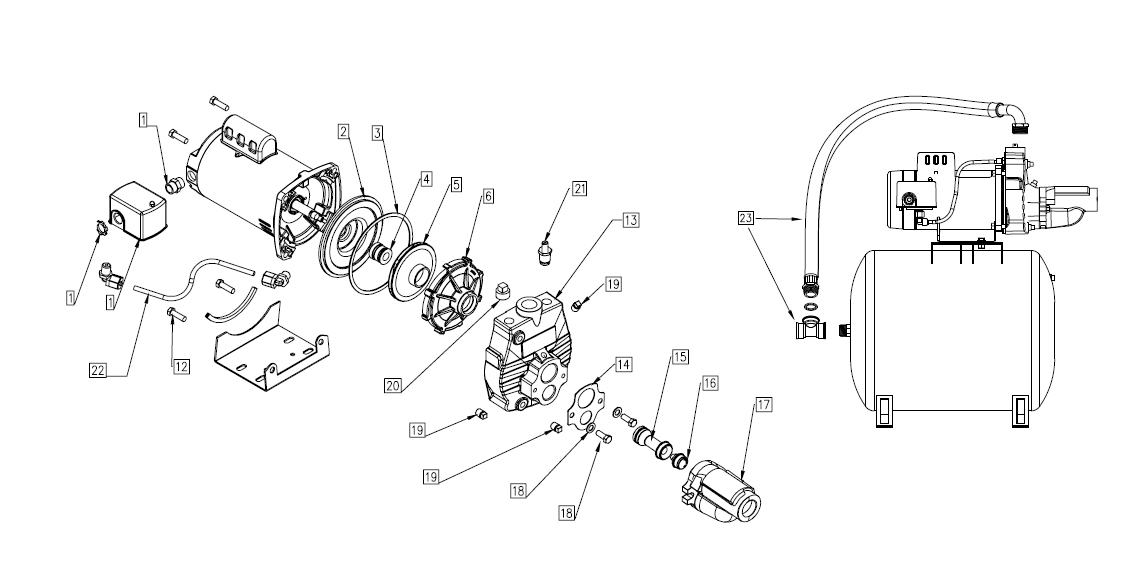

|

Item |

Contents |

Item Description |

Where Used |

|

|---|---|---|---|---|

|

305584002 |

2 |

Seal Plate Kit |

RJC-50-PREM |

RJC-75-PREM |

|

305584009 |

3, 5, 6 |

Impeller/Diffuser Kit |

RJC-50-PREM |

|

|

305584010 |

3, 5, 6 |

Impeller/Diffuser Kit |

RJC-75-PREM |

|

|

305584012 |

3, 4 |

Shaft Seal Kit |

RJC-50-PREM |

RJC-75-PREM |

|

305584014 |

1, 22 |

Pressure Switch Kit |

RJC-50-PREM |

RJC-75-PREM |

|

305584024 |

22 |

Tube Kit |

RJC-50-PREM |

RJC-75-PREM |

|

305584015 |

13 |

Case Kit |

RJC-50-PREM |

RJC-75-PREM |

|

305584016 |

14, 15, 16 |

Nozzle/Venturi Kit |

RJC-50-PREM |

RJC-75-PREM |

|

305584019 |

3, 4, 5, 6, 14, 15, 16 |

Overhaul Kit |

RJC-50-PREM |

|

|

305584020 |

3, 4, 5, 6, 14, 15, 16 |

Overhaul Kit |

RJC-75-PREM |

|

|

305584022 |

3, 12, 14, 18, 19, 20, 21 |

Gasket/Hardware Kit |

RJC-50-PREM |

RJC-75-PREM |

|

305584023 |

17 |

Injector Housing Kit |

RJC-50-PREM |

RJC-75-PREM |

|

640005 |

23 |

Pump/Tank Hardware Kit |

RJC-50/RL6H |

RJC-50/RL14H |

| Model | Item Number | UPC | HP | Volts | Amps | Intake | Discharge | No. of Pipes | Suction Lift | Discharge Pressure (PSI) | Max. Pressure PSI | Max. Head | Max. Flow GPM | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 40 | 50 | 60 | |||||||||||||

| Gallons Per Minute | ||||||||||||||||

| RJC-50-PREM | 602136 | 0 10121 15110 9 | 1/2 | 115/230 | 14.4A @ 115 V 7.2A @ 230 V | 1-1/4″ FNPT | 1″ FNPT | 1 | 5′ | 14.2 | 10.2 | 5.9 | 1.8 | 64 | 149′ | 14.2 |

| 15′ | 13.5 | 9.1 | 4.4 | – | 60 | 139′ | ||||||||||

| 2 | 25′ | 9.6 | 7.4 | 2.4 | – | 56 | 129′ | |||||||||

| 30′ | 5.8 | 3.7 | 1.8 | 0.2 | 62 | 143′ | ||||||||||

| 60′ | 4.3 | 2.7 | 1.4 | 0.3 | 63 | 146′ | ||||||||||

| 90′ | 1.6 | 0.7 | 0.1 | – | 51 | 119′ | ||||||||||

| RJC-75-PREM | 602137 | 0 10121 15111 6 | 3/4 | 115/230 | 17.6A @ 115 V 8.8A @ 230 V | 1-1/4″ FNPT | 1″ FNPT | 1 | 5′ | 16.2 | 12.2 | 8 | 3.7 | 68 | 158′ | 16.2 |

| 15′ | 14.3 | 10.6 | 6.1 | 1.3 | 64 | 147′ | ||||||||||

| 2 | 25′ | 9.8 | 8.9 | 4.7 | – | 61 | 141′ | |||||||||

| 30′ | 7.2 | 4.8 | 2.8 | 1.2 | 69 | 159′ | ||||||||||

| 60′ | 5.4 | 3.7 | 2.2 | 1.1 | 73 | 169′ | ||||||||||

| 90′ | 2.2 | 1.3 | 0.4 | – | 58 | 133′ | ||||||||||

| RJC-100 | 602038 | 0 10121 12284 0 | 1 | 115/230 | 16.4A @ 115 V 8.2A @ 230 V | 1-1/4″ FNPT | 1″ FNPT | 1 | 5′ | 19.9 | 16.7 | 11.1 | 5.6 | 71 | 164′ | 20* |

| 15′ | 14.1 | 13.6 | 8.7 | 3.3 | 67 | 154′ | ||||||||||

| 2 | 20′ | 10.5 | 7.3 | 5.2 | 3 | 87 | 201′ | |||||||||

| 50′ | 7.2 | 5 | 3.4 | 1.9 | 74 | 171′ | ||||||||||

| 90′ | 3.4 | 1.9 | 0.7 | – | 57 | 131′ | ||||||||||

| Model | Length | Width | Height | Weight | Carton Cubes(cu ft) | Pallet Quantity | Qty. per Layer | Layers per Pallet |

|---|---|---|---|---|---|---|---|---|

| RJC-50-PREM | 10.5″ | 20″ | 10.5″ | 43.8 | 1.28 | 32 | 8 | 4 |

| RJC-75-PREM | 10.5″ | 20″ | 10.75″ | 45.7 | 1.31 | 32 | 8 | 4 |

| RJC-100 | 10.33″ | 20.25″ | 11.5″ | 38 | 1.39 | 32 | 8 | 4 |

|

PROBLEM |

CORRECTIVE ACTION |

|---|---|

|

Motor will not start |

No power to pressure switch due to blown fuses, open switches or loose connections. |

|

Pump pressure switch not closed. |

|

|

Pump fails to deliver water |

Pump not completely primed. |

|

Suction lift is too great. |

|

|

Foot valve is either not submerged, buried in the mud or plugged. |

|

|

Restrictor valve is fully closed. |

|

|

Pump loses prime |

Air leaks in suction line. |

|

Well draws down too far and requires a tailpipe. |

|

|

Faulty foot valve. |

|

|

For well point installations where pump is losing pressure or unable to prime |

Have an electrician install a low pressure cut-off switch to shut down the pump prior to critical failure. |

|

Install or adjust a restrictor valve to offset available capacity. |

|

|

Add a larger tank (20 gallon or larger) for additional capacity. |

|

PROBLEM |

CORRECTIVE ACTION |

|---|---|

|

Pump delivers water but not at rated capacity |

Leaks in suction or discharge line. |

|

Foot valve, suction line, impeller or nozzle are partially plugged. |

|

|

Suction lift is greater than recommended. |

|

|

Improper setting of control valve on deep well units. |

|

|

Improper impeller rotation or low speed. |

|

|

Venturi or diffuser is plugged. |

|

|

Motor is wired for improper voltage. |

|

|

Low line voltage at motor. |

|

|

Filtration cartridge (if used) needs changing or is not installed properly. |

|

|

Pump starts and stops too often |

Faulty air volume control. |

|

Air leaks in tank above the water level. |

|

|

Incorrect setting on pressure switch. |

|

|

Tank is water logged or incorrectly charged. |

|

|

Foot valve leaks or is stuck open. |

|

|

Can’t remove plugs |

Use socket and ratchet instead of open style wrench. See PLUG DESCRIPTIONS AND SOCKET SIZES. |