APPLICATIONS

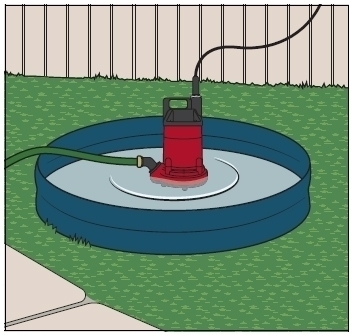

Ideal for general water transfer applications and household water removal in places like basements, crawl spaces, rooftops, and window wells. Also consider using with the RL-SPDK universal hose kit when the application requires moving water up to 24′ away from the site.

FEATURES & BENEFITS

RL25U Multi-Purpose Pump

This submersible multi-purpose pump is designed for clear water transfer applications and household water removal. The pump is for use with water only.

Do NOT use this pump for:

The pump motor is equipped with an automatic resetting thermal protector, and may restart unexpectedly. Thermal Protector tripping is an indication of motor overloading or overheating. This can be caused by application issues such as an obstructed pump impeller, pump running dry, pump air-locked, pump short cycling, excessively high or low voltage supply, or possibly a pump, motor, bearing, or seal that has reached the end of its useful life.

Please examine your pump carefully to ensure that no damage occurred during shipment. If damage has occurred, please contact the place of purchase. They will assist you in replacement or repair, if required.

BEFORE GETTING STARTED

This equipment should be installed and serviced by technically qualified personnel who are familiar with the correct selection and use of appropriate tools, equipment, and procedures. Failure to comply with national and local electrical and plumbing codes and within Red Lion recommendations may result in electrical shock or fire hazard, unsatisfactory performance, or equipment failure.

Know the product’s application, limitations, and potential hazards. Read and follow instructions carefully to avoid injury and property damage. Do not disassemble or repair unit unless described in this manual.

Refer to product data plate(s) for additional precautions, operating instructions and specifications.

Failure to follow installation or operation procedures and all applicable codes may result in the following hazards:

DANGER

Risk of death, personal injury, or property damage due to explosion, fire, or electric shock.

WARNING

High voltages capable of causing severe injury or death by electrical shock are present in this unit.

CAUTION

Risk of bodily injury, electric shock, or property damage.

|

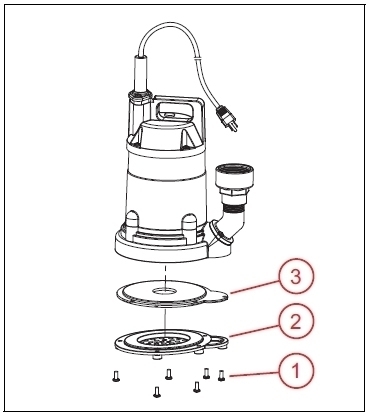

Item |

Part Number |

Description |

|---|---|---|

|

1 |

14942729 |

Discharge/Adapter Kit contains 3/4″ discharge, seals, hardware and 1-1/4″ FNPT adapter |

|

2 |

599002 |

SA-1 Sacrifical Anode (Optional accessory) |

|

3 |

599304 |

Universal 24′ Hose Kit with 1-1/4″ and 1-1/2 adapters (Optional accessory) |

|

4 |

14942904 |

Vertical float switch with 10′ cord (Optional accessory) |

|

5 |

640171 |

Tethered float switch with 10′ cord (Optional accessory) |

|

Model |

Warranty |

Item Number |

UPC |

HP |

Amps/Volts |

Disc. |

Intake |

Cord Length |

Gallons Per Hour at Height |

Shut Off |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

0′ |

5′ |

10′ |

15′ |

||||||||||

|

RL25U |

5yr |

14942730 |

0 10121 00278 4 |

1/4 |

2.5/115 |

1-1/4″ FNPT 3/4″ GHT |

Screened Bottom |

10′ |

1500 |

1250 |

900 |

500 |

19′ |

|

Model |

Length |

Width |

Height |

Weight (lbs) |

Carton Cubes (cu ft) |

Master Pack Qty |

|---|---|---|---|---|---|---|

|

RL25U |

5.9″ 150 mm |

5.9″ 150 mm |

12.6″ 320 mm |

9 lbs 4.05 kg |

0.2538 |

6 |

|

Model |

Length |

Width |

Height |

Weight (lbs) |

Carton Cubes (cu ft) |

Pallet Quantity |

Qty. per Layer |

Layers per Palet |

|---|---|---|---|---|---|---|---|---|

|

RL25U |

18.5″ |

12.6″ |

13.4″ |

55.5 |

1.8076 |

18 Master Packs |

6 Master Packs |

3 |

|

Model |

Phase |

Volts |

Hz |

Amps |

Breaker Size |

Watts |

HP |

Shut Off |

|---|---|---|---|---|---|---|---|---|

|

RL25U |

1 |

115 |

60 |

2.5 |

10 A |

230 |

1/4 |

19 ft (5.8 m) |

|

Problem |

Probable Causes |

Corrective Action |

|---|---|---|

|

Pump does not turn on |

Pump not plugged in. |

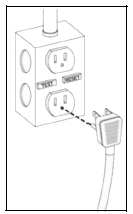

Connect pump power cord to a GFCI circuit. |

|

Circuit breaker off or fuse removed. |

Turn on circuit breaker or replace fuse. |

|

|

Corroded power cord plug prongs. |

Clean prongs on power cord plug. |

|

|

Tripped overload. |

Allow pump to cool, investigate cause (i.e. jammed impeller). |

|

|

Defective motor. |

Replace pump. |

|

|

Pump runs but does not dis– charge fluid |

Blocked or jammed impeller. |

|

|

Suction lift is too high. |

Reduce the pump height to water source. |

|

|

Inlet to impeller plugged. |

||

|

Pump does not deliver rated capacity |

Lift too high for pump. |

Check rated pump performance. |

|

Partially blocked inlet. |

Clean inlet. |

|

|

Impeller or discharge pipe is clogged. |

Pull pump and clean. Check hose for kinks or blockage. |

|

|

Impeller wear due to abrasives. |

Replace pump. |