Why does a pump lose power right when you need it the most? Many owners discover that worn cylinder head components are often the cause. If you are searching for dependable parts that keep your equipment running strong,

PDT3A Engine Honda Cylinder head Repair Parts provide a simple way to restore performance. This page explains what these parts do, how they support your Wacker Neuson diaphragm pump, and how Ken’s Distributing helps you choose the right components with confidence.

Read More

Understanding the Role of the PDT3A Engine Honda Cylinder Head

The cylinder head sits at the top of your Honda GX120UT2QX2 engine. It seals the combustion chamber, supports airflow, and controls temperature. When it becomes damaged, the engine may lose compression or stall under load. A pump that struggles to move water can slow a job or even halt it.

Many users come here asking what symptoms show a failing cylinder head. The most common signs include weak output, hard starting, overheating, or higher fuel use. These issues often point to warped surfaces, worn valves, or cracked housings inside the head assembly.

Why Cylinder Head Condition Matters

A healthy cylinder head supports:

- Steady compression

• Clean air intake and exhaust flow

• Reliable ignition

• Proper pressure for diaphragm pump cycles

A worn head creates gaps that leak pressure. Even a small leak can cut pump performance sharply.

Key Features of Wacker Neuson PDT3A Diaphragm Pump Cylinder Head Parts

Each part in this assembly works together to maintain smooth engine function. High-quality replacements help restore output levels on every job.

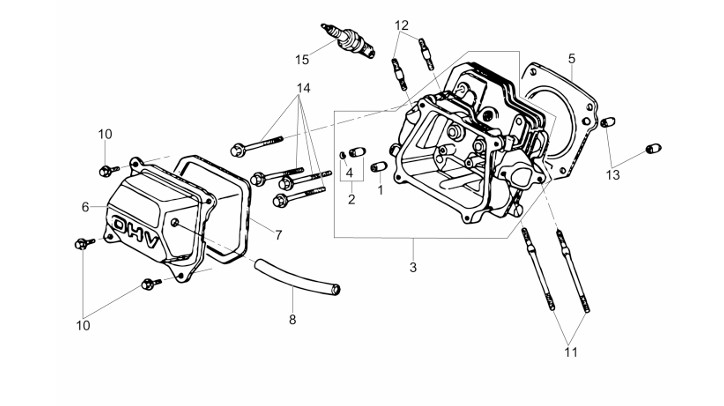

You will find components such as:

- Valve sets

• Springs and retainers

• Head gaskets

• Rocker arm hardware

• Complete head assemblies

These parts match the PDT3A Engine Honda gx120ut2qx2 Repair Parts specifications to ensure proper fit. This reduces guesswork and lowers the chance of future breakdowns.

When to Replace a Cylinder Head or Its Components

A replacement becomes necessary when you notice:

- Loss of pressure under load

- Visible cracks or worn materials

- Persistent misfires

- Oil entering the combustion chamber

- Repeated overheating

A simple inspection can confirm these issues. Many owners choose to replace the full head rather than individual parts when damage is severe.

Benefits of Choosing Ken’s Distributing for Cylinder Head Parts

Ken’s Distributing supplies parts that meet or exceed factory requirements. The focus is on dependable stocks, an accurate fit, and simple ordering. Each part follows the original Honda design pattern used in the PDT3A Engine Honda Cylinder head system.

Customers appreciate:

- Quick access to compatible components

• Trustworthy brand-name replacements

• Straightforward selection for Wacker Neuson pumps

• Option to view related pump parts on the site

If you need additional items for the pump itself, you can explore the Wacker Neuson pump section here:

https://kendisco.com/products/water-pumps/

Later in your repair process, you may also find helpful components in the Wacker Neuson catalog:

https://kendisco.com/products/water-pumps/wacker-neuson/

These links offer clear navigation without overwhelming the reader.

How Cylinder Head Problems Affect a PDT3A Diaphragm Pump

Your pump depends on steady, rhythmic engine power. A failing head disrupts this rhythm. A small leak in the head gasket can increase heat. A warped valve seat may reduce airflow. Each issue lowers the engine’s ability to maintain torque.

If your pump output drops, the engine often shows strain before the pump components do. Replacing the cylinder head assembly or related small parts usually solves the problem more effectively than adjusting pump components alone.

What Happens Inside the Engine During Normal Operation

A simple view of the cycle helps you see why the cylinder head is so important:

- The piston compresses air and fuel inside the sealed chamber.

• The spark ignites the mixture.

• The explosion drives the piston downward.

• Exhaust gases leave through the valve system.

If the head cannot hold pressure, this cycle weakens and the diaphragm pump will not reach its rated flow.

Step-by-Step Guide to Choosing the Right Cylinder Head Parts

Selecting the correct parts is simple with a basic plan.

- Confirm your engine model.

Look for the Honda GX120UT2QX2 marking. This ensures you match the correct specifications for PDT3A pumps.

- Identify symptoms.

Weak compression may require a full head. A ticking noise may require valve parts. Thick white smoke may indicate a blown gasket.

- Compare part diagrams.

Use the pump’s diagram to match part numbers. Each system shows valves, springs, seals, and the head unit.

- Choose full assemblies when damage is severe.

A complete head reduces the time needed for repairs.

Simple Questions That Help You Diagnose the Issue

- Does the pump stall when moving heavy loads?

• Has the engine become harder to start in cold weather?

• Do you notice more vibration than usual?

• Is fuel use higher while output feels lower?

These questions help narrow the cause. If several answers are yes, a worn head or valve set is likely.

How Proper Maintenance Protects Your New Cylinder Head Parts

Routine care reduces future downtime.

- Change oil on the schedule recommended by Honda.

• Keep the air filter clean and dry.

• Check valve clearance if performance changes.

• Store the pump in a clean, dry location.

Small steps help extend both engine and pump life.

Troubleshooting Questions About PDT3A Cylinder Head Issues

Why does the engine lose power under load?

The cylinder head may leak compression, causing the pump to lag.

Why does the engine run hotter than before?

A damaged head gasket or blocked airflow path may restrict cooling.

How long does a head replacement take?

Most repairs take under an hour with basic tools. A complete assembly speeds up the process.

Final Thoughts on Choosing Reliable Repair Parts

A strong diaphragm pump depends on a strong engine. By choosing quality PDT3A Engine Honda Cylinder head Repair Parts, you restore the core power source behind your Wacker Neuson PDT3A system. Ken’s Distributing offers access to accurate, dependable parts that support steady, long-lasting pump performance.